MAPLAN offers a wide range of multifunctional automation modules for process optimisation and shortened cycle times.

- Modular automation kit

- Increase the productivity and energy efficiency of your facility

- Fast and precise movements thanks to efficient servo drives

- MAP.autocell: Individual solutions for fully or semi-automatic production

- Centralised control system of all components with MAP.commander C6

- Additional components can be easily integrated into the cycle configuration

- Integration into the visualisation, diagnostic and alarm system

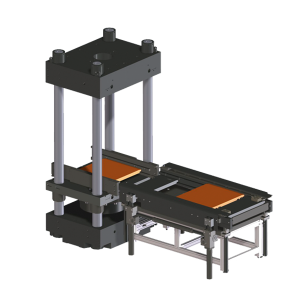

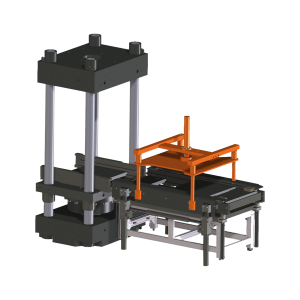

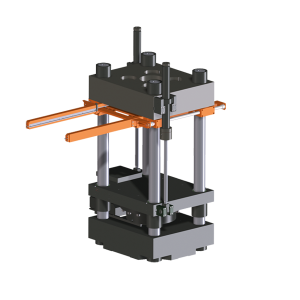

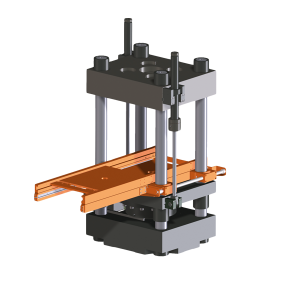

Heating plate shifting / changing

- Heating plate shifting enables improved ergonomics

- Increased output through exchanging the heating plate (two lower mould halves)