PRODUCTION OF LARGE-DIMENSIONED HIGH-PERFORMANCE GASKETS

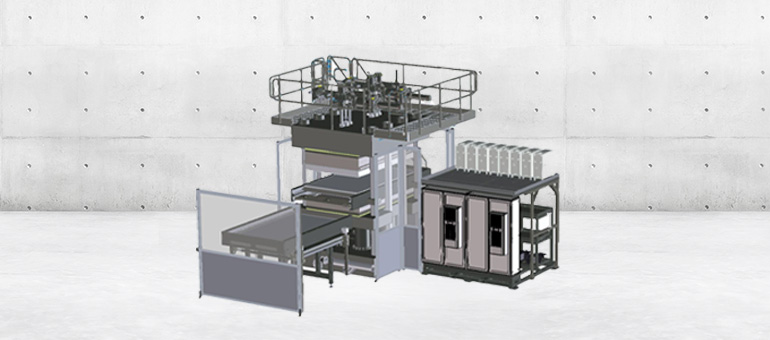

Initiated by the demand for machines that produce large-scale metal bonded rubber composite parts, engine gaskets and gaskets for battery boxes, MAPLAN has developed a new, vertical machine series. The functional specification high-lights are large platen areas, ergonomic operation and at the same time accurate injection volume control. The new MAPLAN vertical machine series SPECIAL+ MR is Stable, accurate and modular and suitable for many challenging applications involving Large size rubber parts with close tolerance.