MAPLAN SPECIAL⁺ MR: The foundation for large size sealings

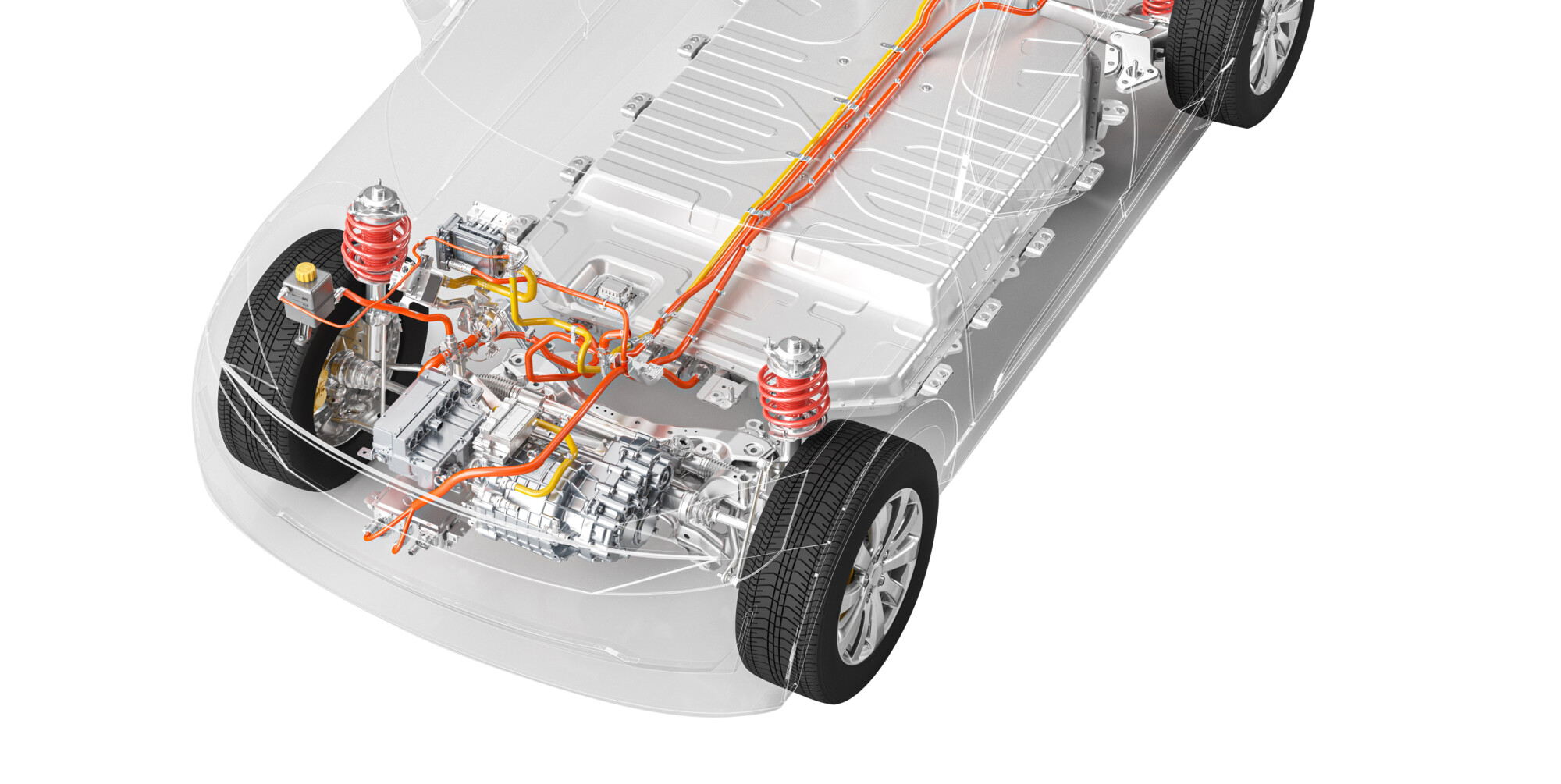

MAPLAN is closely cooperating with producers and users to provide machine solutions for pioneering electrically powered mobility applications. The focus is on increasingly efficient battery/fuel cell technology, which can offer longer mileage range and drive power. For this reason, MAPLAN is developing a new modular and scalable large-scale machine series with vertical clamping unit: MAPLAN SPECIAL⁺ MR, with TWIN RAM 560 as the first model. Machines of this type are ideally suited for producing large gaskets for e-vehicle battery boxes.

PRODUCTION OF LARGE-DIMENSIONED HIGH-PERFORMANCE GASKETS

Initiated by the demand for machines that produce large-scale metal bonded rubber composite parts, engine gaskets and gaskets for battery boxes, MAPLAN has developed a new, vertical machine series. The functional specification highlights are large platen areas, ergonomic operation and at the same time accurate injection volume control. The Series name “SPECIAL⁺ MR” reflects the design principal, where combination of two (TWIN-RAM), four (QUATTRO-RAM) or even more clamping cylinders are used to distribute clamping force evenly across large platen areas and to ensure minimum deflection during moulding.

The new MAPLAN vertical machine series SPECIAL⁺ MR is stable, accurate & modular – and suitable for many challenging applications involving large size rubber parts with close tolerances.

SPECIAL MACHINE IN LARGE-SCALE FORMAT: MAPLAN TWIN-RAM 560

TWIN-RAM 560 (5600 kN clamping force) uses heating platens with size of 800 x 1500 mm designed for maximum deflection of 0.05mm at the center of the plate. For a specific project, the clamping unit was combined with two MAP.fifo injection units with injection volume of 50ccm located from the top of the machine. Two injection units can inject in parallel or independent of each other. These high-precision injection units make it possible to inject very small shot volumes with high precision.

In this specific case, rubber seals are bonded on cylinder head gaskets, using this special machine. The gasket consists of thin rubber lips injected around cylinder bores, fi xing holes etc. over the metal gasket. The entire injection volume of rubber is only 2 x 7ccm for one part. High-precision gaskets with vary large dimensions and that do not require post moulding operations like flash removal, can be produced with these machines.

TWIN-RAM machines are available with various shuttle systems to make loading and unloading of inserts and gaskets very easy. Moreover, various automation possibilities are also available from the MAPLAN portfolio.

THE MARKET DEMANDS FLEXIBILITY – MAPLAN RESPONDS

OEMs and machine producers are challenged by the complex special requirements of e-mobility. New challenges will emerge regularly as various future applications are developed driven by E-mobility. MAPLAN is ready for this challenge and, in addition to the existing and proven machine program, has developed another new machine segment by which the large gaskets can be efficiently produced with high precision. This is how MAPLAN takes challenges positively and will be there for our customers to depend on us. Electromobility is important for the future of all people on the planet and also a major concern for MAPLAN. e-mobility is practiced within our organization as the part of MAPLAN’s sustainability strategy.

TWIN-RAM 560 with 2 x 2800 kN clamping cylinder and 2 50-cm3 MAP.fifo injection units that are injected from the top.