MAPLAN machines are known for their fundamental consistency, their user-friendly interface design and the versatility of their settings to configure and simplify the production process. The latest version of the intuitive touchscreen interface between user and machine boasts a 30 percent faster touch response time compared to

its predecessor. With only one basic control and operation method, all MAPLAN models can be operated in the same way. The MAP.commander functions as the central unit: no matter the upgrade level – from the smallest and simplest machine to the high-end system with full automation.

CONTROL INTELLIGENCE

MAP.commander generation C6

The intelligence of the MAPLAN machine

Smart process control

Increased efficiency through individualisation

- Drag & drop cycle configuration for up to five parallel sequences

- MAP.logicmoves: Freely programmable control of external equipment

- Valve gated cold runner: up to 32 valve gates individually controllable

- MAP.motion: Self-optimising movements of the clamping unit / ejector

Secure access and data

- User-specific rights system

- Archiving of cycle configuration, process parameters and alarm protocol

Foresight instead of hindsight

- Diagnostic display features traffic light system and targeted operator guidance in the event of an error

- Alarm system with help function

- Maintenance program recommends maintenance activities

Be connected!

The advantages of networking and digitisation speak for themselves. Industry 4.0, which is sadly often only used as a buzzword, promises real advantages when it comes to production, planning, control and maintenance. In order to take full advantage of these benefi ts, MAPLAN production cells and machines can be connected to server systems to deliver production data to MES systems.

- Every MAPLAN machine with the new MAP.commander C6 control is network ready

- Authorised users can access the machine at any time and from any location via VPN connections

- Real-time control of production progress – or through log files and reports

- MAP.mes: Extensive MAPLAN interface for MES systems based on OPCua protocol

- MAP.mes77: Standardised interface to industry 4.0 features provides data for MES systems: Monitoring, statistics, support, remote maintenance, etc.

- Integration into higher-level ERP systems, e.g. via T.I.G.

- Central documentation of processes and recipes

MAP.remote

Remote maintenance – optional with MAP.eye camera – guarantees immediate assistance from the MAPLAN service or process technician team.

- Always up-to-date with remote updates (no flashcard required)

- Instant online support guaranteed

- No service technician onsite required. Therefore, no travel expenses arise.

Hardware

Regardless of whether in the standard 15“ or luxurious 21“ design: both function according to a simple operating concept, which makes even the most complex processes understandable and transparent. Due to the web based HTML5 technology, the MAP.commander software can be accessed from any other device such as a laptop, iPad etc. in the user’s chosen language withpersonalised access rights. This gives the user remote access to the machine settings and data. With appropriate configuration and access rights, the user is even able to intervene in the process remotely. There is no risk of conflict between machine operators and external access.

What are the benefits of the HTML5 technology?

- Flexible: web-based and platform-independent – can be used with any device

- Practical and simple: the user interface looks the same on every device

- Efficient: saving of formulas and processes

- Transparent: remote access to monitoring and statistics data

- International: one application – countless languages

Usability & Visualization

Why is easy usability of the MAP.commander C6 so important?

The machine operator receives ideal support, even for very complex production processes: this makes the work easier, shorter training times are required, reduce user errors and in the end increased efficiency.

- MAP.varioswitch: best ergonomics and operating safety with the intelligent combination of freely configurable software and hardware buttons

- Hot Key bar: quick access to all essential machine functions

- MAP.smartlight: the visualization of machine state is optimal for multi-machine operation

- Enables glove operation

- WYSIWYG – Only what is needed is displayed

- Standard display in national language and English

- Large, easy-to-read font size

- 30% quicker touchscreen response time

More efficient through customisation

Faster cycle times and higher productivity with the MAP.commander C6?

Benefit from numerous customisation options as well as passive and active assistance systems for faster machine set-up and optimised motion sequences.

Tailor-made according to your processes

- Individual user pages with freely definable fields

- MAP.logicmoves: freely programmable control of the external equipment (electric, servoelectric, pneumatic, hydraulic)

- Drag and drop cycle configuration for up to 5 parallel sequencers

Production made easy

- MAP.motion: Self-optimizing movements of the clamping unit / ejector

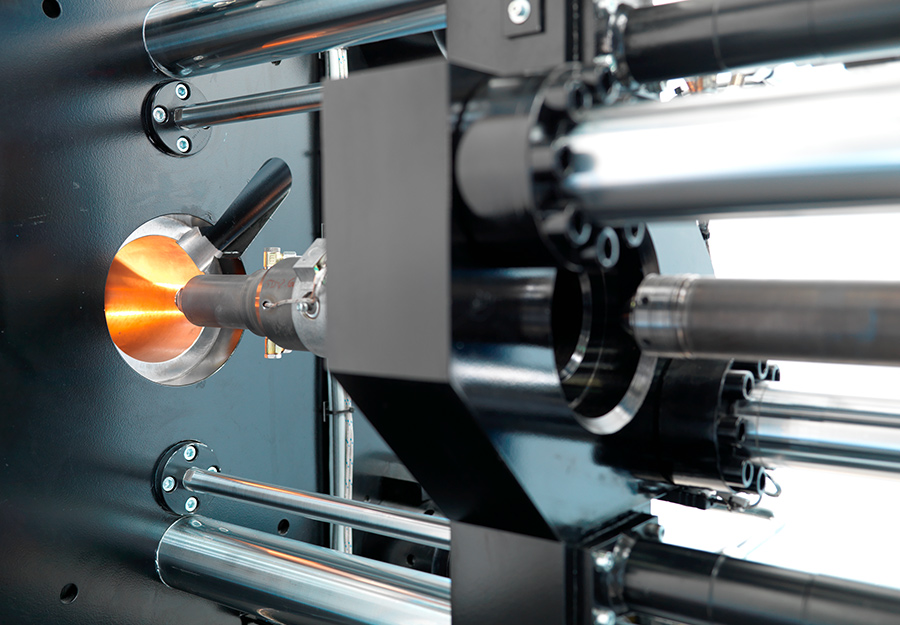

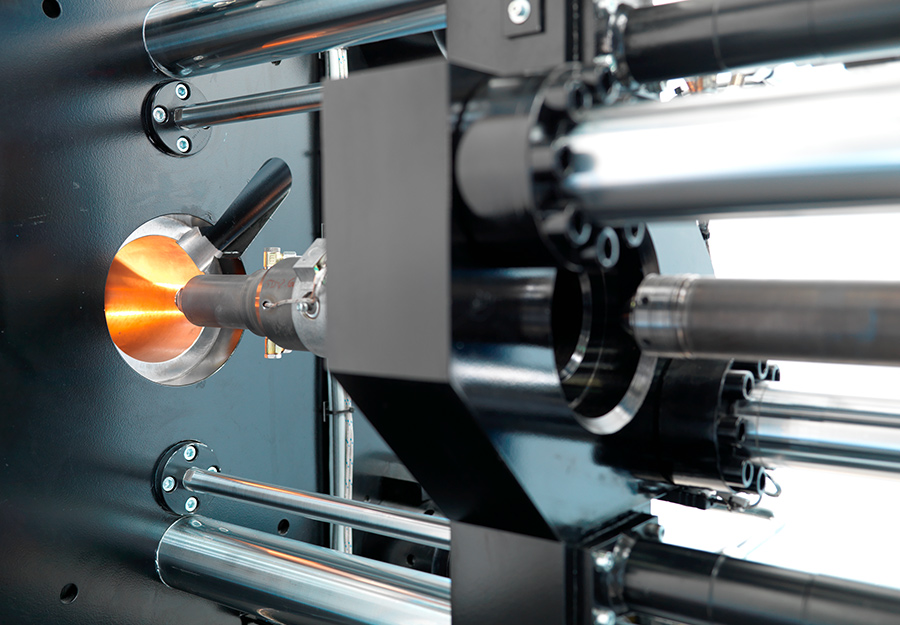

- Cold runner control for up to 64 needles (32 individually controllable)

- No machine downtime when somebody interrupts in the photocell during the cure time

- Non-contact and maintenance-free, ultrasonic path measurement for the clamping unit and ejectors

- Heater timer with intelligent manual control for the preheating before shift start

- MAP.autofeed: Automatic strip intake for continuous production

- MAP.slomo: Jerk-free, precise opening of the clamping unit for the demoulding of sensitive products

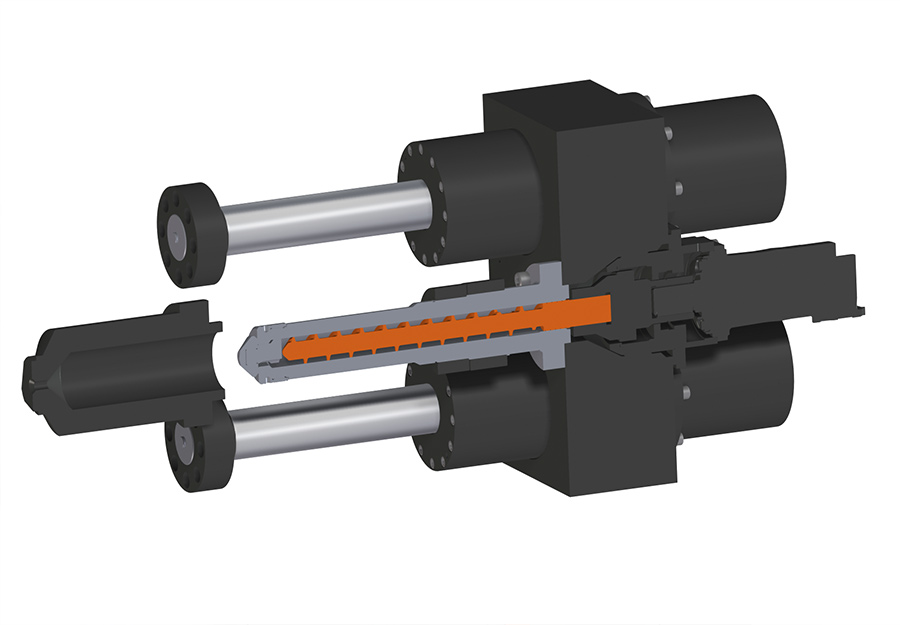

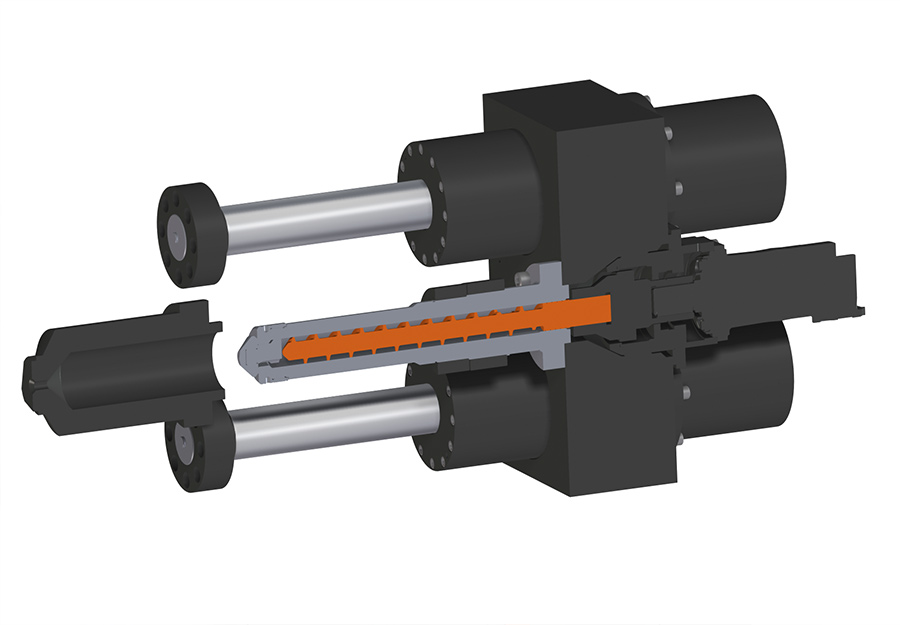

- MAP.multidosing: multiple dosing for larger volumes, multiple injection and plasticizing

Diagnosis & security

- User-specific rights system

- Login via RFID or USB

- Documentation of cycle configuration, process parameters and alarm log

Prevention is better than cure

- Diagnostic display features traffic light system and targeted operator guidance in the event of an error

- Alarm system with help function

- Our maintenance program recommends maintenance activities

Understand, what is going on

- MAP.energywatcher for energy monitoring is available in 3 versions: MAP.powerwatcher, MAP.waterwatcher, MAP.airwatcher

- MAP.currentcontrol: Monitoring of the heating current

- MAP.moldsafe: Digital tool protection

MAP.advanced

Do you always use your machines to their fullest potential?

With the MAP.advanced package you can visualise your injection process in order to determine the best possible process and guarantee the highest part quality.

Process graph / injection graph

- Curves visualise the injection speed, injection pressure and position of the injection piston

- Analysis of alarms including support for the process development

- Documentation of transfer processes

- Values can be exported as .csv file

MAP.limit envelope curves

Envelope curves simplify the monitoring of the injection process and can be used to optimize processes, avoid waste and and increase productivity.

Plasticising graph

Curves for screw speed, back pressure, hydraulic pressure and temperature are documented during the plasticising process.

Trend graphs

- Documentation of all process-relevant parameters for the quality documentation and control of produced part

- 10 trends with up to 12 process values are displayed in graphs and tables

- Individually configurable

- Limit value monitoring

- Values can be exported as .csv file